Ear Protection Headset Redesign

Redesigning noise cancellation headsets with Human Factors principles

Human Factors | Product Design

Background

The headset and how it reduces sound

This project focused on the redesign of a noise cancellation headset so that the unique noise-blocking technology can be maintained, but comfort and usability aspects of it can be improved.

The headset was a passive noise cancellation device that used a patented sound reduction chamber to enhance low frequency attenuation. This product could be employed in both industrial and domestic environments.

It aimed to protect hearing up to 31dB while allowing speech sounds to be heard.

However, user evaluation tests of the current device found that while the product was effective for sound reduction, it was unacceptably uncomfortable when worn over a 12-hour work shift and difficult to put on and keep in place.

The Headset

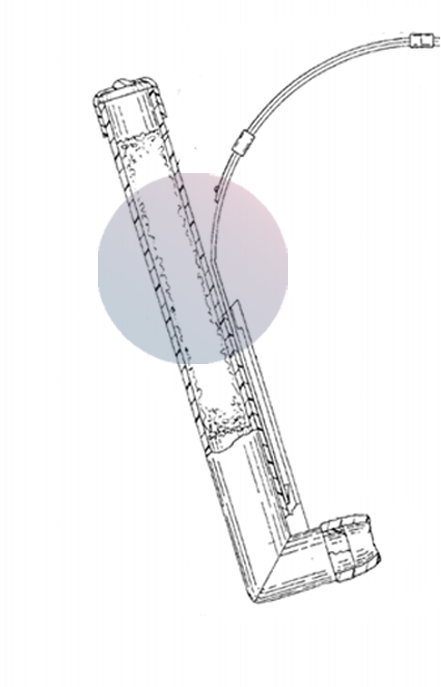

The product muffler tube was it main source of sound attenuation using passive noise cancellation.

The product was meant to be worn over the head and rested on the concha of the ear effectively blocking outside noise.

To maintain the noise cancellation, it would be important to maintain the length and diameter of the muffler tube as any changes would affect the effective frequency of sound it was cancelling out.

How it works and how it is worn

Persona

We created a persona to better visualize how a typical user would use this device. It would be important to keep the user in mind when redesigning the product.

The prime demographic for the project was factory workers and users that would often use loud equipment.

Analysis of the headset

As a part of this project, existing data as well as expert reviews conducted using a Delphi-method analysis were compiled. Below are a list of the most important usability issues that were identified.

Connecter tube

The ear tip does not fit into the ear easily

Diameter of the ear tip is too large and thus hurts the concha

The headset stays on the head through clamping pressure. Over time, this hurts the cartilage in the ear

Ear Tip

Has a foam earbud that is meant to be replaceable

Foam does work in all weather conditions

Foam earbuds get dirty, absorb moisture and are not hygenic

Headband

Hair can get stuck in the headband

Cannot be worn with helmets or other gear

Strap is thin and not sturdy

Headband Connecter

Product is not strong & durable

Designed to fit most users but fails to do so

A mid-range product; does not gave a high-end feel

Design:Brainstorming and affinity diagramming session

This session used the data compiled from a review of the Delphi-method data, observational data, and the technological patents through which the headsets were designed,

Work activity affinity diagram (WAAD) of our brainstorming session (representation)

Prototyping

Rapid prototype methodologies such as clay modeling or 3D printing were used to test different configurations.

Each prototype was weighed against the overall system requirements and iterated upon.

Careful inspection of the patent of the muffler tube showed that the tube only required to have the same length and diameter, therefore, we could change its shape without compromising on noise reduction.

Prototype #1: U-Shaped muffler tube, inner-ear, made with modeling clay

Prototype #2: oval muffler tube, inner-ear, made with modeling clay

Prototype #3: 3D CAD rendering of coil shaped muffler tube

Prototype #3: 3D printed rapid prototype of CAD model

Final Design

Headband

The headband now went behind the head, rather than over the head as many factory workers required headgear.

Workers can rest the headset on their neck and shoulders during breaks.

This reduces hair contact with a headband.

Muffler tube

The muffler tube shape was changed to a coiling shape to make it easily fit into the muffler and improve durability.

This was possible since length and diameter stay the same maintaining the passive noise cancellation properties claimed by the original design.

Earpiece

Designed to encircle the ear, distributing the majority of band pressure to the head rather than ear cartilage

A ball and socket joint allows the modified connector tube to be inserted at any angle allowing for adjustment.

Ear tip

Used visco-elastic ear tips instead of existing ear tips.

These are biocompatible and take the shape of the concha over time.

Viscoelastic material act like liquids under slow gradual pressure increases and solids when pressure is suddenly applied.

Great for comfort and blocking sounds

Covering

The headband is also now covered with Goretex material which forms a layer over the headband.

This material provides all-weather protection.

A foam insert between the Goretex fabric helps cushion ear and reduce pressure on the concha.

Design Summary

Behind the head configuration

Flexible, thin and lightweight plastic band

Designed to encircle the ear

Coiled muffler tube to help improve durability, reduce bulkiness and improve aesthetics

Goretex fabric cover to allow use in multiple work environments and weather conditions.

Fabric improves aesthetic feel and durability.

Foam insert between Goretex and coiled tube to improve comfort

A viscoelastic ear insert improves comfort and improves the seal

Collaborators.

Amy Harvey

Harsh Sanghavi

Nayara Faria

Vaishakhi Suresh

Advisor.

Dr. John G. Casali

Year.

2018

Category.

Product Design

Human Factors Engineering